When Deploying Internet of Things Projects, Technology Is the Easy Part

Internet of Things deployments are often solutions looking for problems. But the number of impressive and pragmatic IoT use cases is steadily growing, says a Dell EMC SVP.

May 12, 2017

If someone calls you up and says, “Hey, I want to talk to you about Internet of Things,” it’s easy to get the impression that, first, you are not sure what they are talking about and, second, that they might not know what they are talking about. After all, this person could be a hobbyist who wants to hack together a DIY IoT project in their living room. They could also be a machine builder or a business professional who knows just enough about IoT to be dangerous.

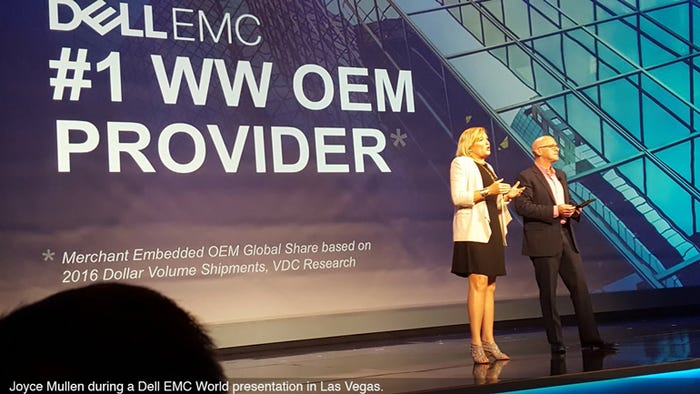

“IoT is such a general term, and it can mean so many different things,” says Joyce Mullen, senior vice president and general manager, global OEM and IoT Solutions at Dell EMC.

The vagueness of the buzzword, combined with its vast business potential, can prevent organizations from first identifying a clear problem that the technology can address. When asked how significant this problem is, Mullen says, without batting an eye, that it’s “huge.” “We won’t deploy our sales team unless we understand what the problem is that the organization wants to address,” she says. “Unless you start with the problem, you can’t possibly talk about deploying a solution.”

Another consideration, she says, is that some tech companies frame IoT as a vast and complex technology. “I am not going to mention any names, but if you make your money on broad and complicated [projects], and having big consulting contracts over many years that extend across many business divisions, you want to keep it that way.”

Mullen says that Dell’s IoT group works best with customers that take a pragmatic approach—those that have clearly identified a business case for the technology.

In the following Q&A, Mullen outlines the steps needed to launch a successful IoT project, comments on the IT/OT integration, and shares her favorite IoT use case. She also explains why her prior experience as a plant manager at Cummins Engine Co. helped her understand IoT more than her Harvard MBA has.

What are the main steps for launching an IoT project?

Step One: Identify the problem you are trying to solve. Have you attempted to address this problem in other ways?

Step Two: Figure out what your infrastructure looks like. What data do you already have?

When we get through one and two, there is often an answer that is pretty simple. Then it becomes a matter of figuring out how to layer in the right kind of analytics and maybe weaving in some new sensors and some computing power.

When identifying a problem to address with IoT, our customers almost never conclude that they need to monetize all of their data assets. That comes later—after they have started collecting data and understanding what it is.

I think having a wait-and-see approach is reasonable. Until you start using data and figuring out what it tells you, you really don’t know what the opportunity is. We have seen that theme in every scalable case. You start with a small problem and it gets to be a bit bigger over time. Once you roll it out, the art of the possible starts to become apparent. You get a sense of what you can learn from the data and how you might compare it across departments or factories or maybe even industries. Start small with a real problem you can fix and get a return on. I think the smaller you start, the more effective you are going to be.

Could you provide an example of this approach in action?

We have a customer focused on cold-chain management. Thirty-three percent of the food in the supply chain goes to waste, according to UN estimates. If we could solve this problem, we could literally feed the hungry.

There is not good temperature control in the supply chain. So food gets to be the wrong temperature and become unsafe, and you have to chuck it.

One of the things we found is that it is common to have sensors in refrigerator units in the stores. But most of those sensors are not connected to anything. We are working with a major supermarket chain to layer in analytics and computing capability and link that up to the existing sensors. That is a practical solution to a common problem. You can send alerts to people in the grocery store when a refrigerator unit isn’t operating at the right temperature.

Any other advice for launching IoT projects—other than clearly defining the problem up front?

We recommend that companies start small. After you have identified the problem you want to tackle, figure out what you think the solution is and test it.

Once you have done that pilot, think about things like how you design security and manageability into it. How do you scale it? Then you can figure how to put together a rollout plan.

There is a lot of knowledge sharing that has to happen.

We find that even though this approach can feel slow in the beginning, it is a whole lot faster than when you try to start really big, and you just get bogged down.

The other thing we’ve learned is that it is easy to underestimate the complexity of an IoT project. You can’t just buy a ready-made IoT solution. You have to figure out who can design this thing, who can install the sensors, and the whole cultural piece.

When it comes to IoT, technology is not the hard part—it’s the business processes around it. You have the business processes around the IoT deployment and the business case development. For instance, what happens to the returns you get from an IoT project when they cut across departments?

If you are in the food handling business and you’re the facilities guy, you are only looking at operational expenses of your refrigeration units. You don’t get the benefit from preventing food from spoiling and being thrown out.

How would you summarize Dell’s approach to navigating the gulf between operational technology and information technology?

When we are working with our customers, we sometimes see that we are the ones introducing their operating technology and IT people.

Bringing the two together isn’t easy.

If you are in a production environment, you care about things like yield, scrap, safety, quality, uptime, and maintenance intervals. If you are in IT, you are thinking about security, governance.

Figuring out how to get those guys working together towards the same aims is a challenge. There is a wide variety of applications, whether you are hooking up a factory, vehicles, or the food supply chain. Sometimes our IT guys say, What is all of this stuff?

If everyone connected their cows, you could really help these farmers.

There is a lot of knowledge sharing that has to happen. We love it when we can help bring those two together because when we do, everybody figures out how they can help each other. That’s when things truly get done. And that is where we have had the most success.

What is your favorite case study?

The Internet of Cows! The Chitale Dairy in India has RFID tags on the cows that collect information about how long they eat and their activity levels. They map that against their vaccination history and who the parents were and the cow’s lineage. You can figure out what behavior drives the most milk production. This dairy in India is not only doing this for their own herd, but when they sell cows to other villagers and connect those so they get all of the same data. It is the coolest story! It gives me chills because this technology is so available and you can help these families who don’t have much more than their cows.

Think about how scalable that is. If everyone connected their cows, you could really help these farmers.

How does your background as a plant manager at Cummins Engine Co. and your Harvard MBA inform your view of IoT?

Being on a factory floor at Cummins was a really great experience because it helped me understand what is going on in these operating technology environments. It helped me understand how processes work and how people learn in those environments. That has been super helpful—way more valuable than my Harvard MBA. Seriously, it’s about the people and the process and not the technology.

About the Author(s)

You May Also Like