Survey: Why IT/OT integration is so tough

Though crossing the OT/IT divide is not easy, our recent survey and executive interviews shed light on the topic.

July 26, 2017

If you’ve heard anything about IT and OT, you are aware that the two domains are converging. Gartner declared as much in 2011.

But the workers who specialize in operational technology — the hardware and software that monitors industrial machinery, power stations and the like — seem to be cut from a different cloth than traditional IT professionals. A survey conducted in April 2017 by IoT Institute and the Industrial Internet Consortium that focused on professionals who had active IIoT initiatives underscored the differences. We surveyed 115 professionals across a range of industries, 48.7% of whom had implemented multiple IoT projects. Interviews with IIoT leaders provided context for our findings.

For instance, Andy Rhodes, vice president and general manager of IoT commercial solutions at Dell, described how he was visiting an industrial firm and speaking with that company’s IT staff. Then, an employee at that same company walked over and said to him: “Oh, you people at Dell always bring such a big entourage.” Surrounded by members of the firm’s IT department, Rhodes was the only person there from Dell. Moments later, he realized that many of the members from the company’s IT and OT departments had never met. Rhodes would soon find himself in the position of introducing the two groups.

Mind the gap

Rhodes’ anecdotal experience reflects the gulf that exists between many companies’ IT and OT divisions. Yet the two groups must come together if IoT projects — and broader digital transformation initiatives — are to succeed. “If people within enterprise companies see digital transformation as yet another IT project, then most of their efforts are bound to fail,” said Vivek Bapat, senior vice president, global head of marketing strategy and thought leadership at SAP. Dave McCarthy, senior director of products at Bsquare, agreed, stating that internal political struggles that prevent IT and OT teams from coming together can slow IoT projects.

Our survey, which focused on professionals with IoT experience under their belt, underscored the type of cross-functional teams that should ideally support IoT projects. When asked which roles should be involved in an IoT project, executives were cited by 72.2% of respondents while engineering and software/hardware development professionals were cited by nearly as many: 70.4%. IT and operations staff came in at 66.1% and 58.3% of respondents, respectively. Next in line was marketing/customer service, with 40.9%, and systems integrator partners, with 38.3%.

Daniel Elizalde, a Stanford instructor and founder of TechProductManagement, said that the fact that IT ranked a bit higher than manufacturing in the survey may highlight bias between the two groups. “Many IT professionals, for instance, tend to view OT as a necessary evil,” Elizalde said. “There is usually a divide between people who are working on the floor in manufacturing who are integrating all of the [industrial control] systems and the people working in IT who expect them to just work,” he said.

Still, it is difficult to generalize about IT and OT teams because there is so much variability among companies with active IoT projects, said Dell’s Rhodes. “At some companies, OT seems like the bottleneck,” he said. At others, IT is the bottleneck because issues such as compliance, governance, security and data center requirements can test the patience of motivated machine builders. “It really is cultural and depends on the company in question. I think it is all over the map, which is the same with anything in IoT,” Rhodes explained. “If there is one thing I’ve learned, there are polar opposites everywhere in IoT.”

Bringing the two together

Industrial companies that report success with IT/OT integration efforts tend to stress the importance of listening and winning buy-in that extends across stakeholders. “Successful Industrial IoT initiatives start by establishing a cross-functional team that represents all stakeholders,” explained Bsquare’s McCarthy. “Since confidential company data is at the core of these solutions, this typically goes beyond IT and OT to include legal and other corporate governance functions.”

Sanjay Khatri, director of product marketing, IoT services at Cisco Jasper, agreed that it is important for enterprise and industrial companies to plan on IT/OT integration as early as possible in a project. Not long ago, many vendors treated the subject like an afterthought, he said. “Fast-forward to today and we are seeing a lot more companies talking about integration between their traditional IT and operational or line-of-business side of things right upfront,” he said.

It helps to have a common aim. We asked survey respondents about the current focus of IT/OT integration efforts. Reducing operational costs was cited by 57.9% of respondents, followed by optimizing business processes (57%). Next up were better business intelligence for enterprise decision-making and improving cross-company communications and knowledge, each with 49.1%; improved interoperability and management of standards, with 47.4%; and improved security policies and visibility, with 45.6%.

While cost reduction is a powerful goal for both IT and OT staff, it’s often not enough to unite workers from both sides of the divide. IT and OT professionals also must work to understand the other’s perspective and technologies, said John Peterson, general manager, IT at transmission manufacturer AWNC. “Knowing how to speak IT but listen with engineering ears is critical,” Peterson explained. IT leaders should meet with the manufacturing and engineering team and understand exactly what they are looking for. Then, IT leaders can reflect on those needs and build consensus with OT professionals by explaining how IT investment and programs can improve the manufacturing side of the business. “Then, when you as the head of IT are meeting with executives, it is a much easier sell when you have operations supporting your pitch on IT investment.”

Achieving such an alignment between OT and IT, however, is an ongoing process, stressed Dan Wiggins, vice president of manufacturing and IoT solutions at Cisco. “People need to understand that once you start connecting all of these devices, machines and robots, that is when the real work begins,” he said. “You have security concerns. You also have data flows and questions around what you want to do with the data: Do you want to analyze it immediately or put it into a larger analytics engine or send it to the cloud?”

Some companies are beginning to enlist the help of a single executive to help unify IT and OT groups. “Occasionally, we come across titles that are chief information officer or chief IoT digital officer or chief IoT officer,” Cisco Jasper’s Khatri said. “We are seeing this at some of the leading companies in the industrial IoT side. They understand that they need to have someone who can bridge that gap and be the champion on both sides.”

The notion of having a point person manage the success of IoT projects is gaining ground, Elizalde said. “You need to have somebody whose job description includes aligning OT and IT, otherwise, without that clear mandate from the executive team, it becomes really hard to align the teams,” he explained. It is important for C-level IoT professional to work on re-defining the goals and success criteria of each department to foster collaboration, he stressed. “The challenge is that IT and OT have different goals, are compensated differently and have a different philosophy,” he added. Companies that simply encourage IT and OT to “just work together” will likely find a lot of resistance between the two groups. “For example, IT teams have strict policies of how and when to connect devices to what they think of as ‘their’ network,” Elizalde explained. “That’s one of the key pieces of friction: they are often incentivized to resist connecting new devices and to be protectors of the cloud. That can become an immediate bottleneck and contention point for the OT folks who now are asked to connect their devices to the cloud.”

Other Hurdles

When we asked survey participants about the biggest challenges of IT/OT implementation, the top answer, with 57% of votes, was “overcoming cultural barriers and organizational silos.” Next in line were “blurring of the lines between OT/IT creates tension over who is responsible for what,” cited by 43.4% of respondents, and “IT does not understand how OT works,” with 42.5%. Interestingly, the percentage of IT workers who agreed with this statement (42.9%) was nearly as high as that of manufacturing professionals (45%). Beyond that, 40.7% of respondents selected “tangled web of interconnected components with no central, standardized platform.”

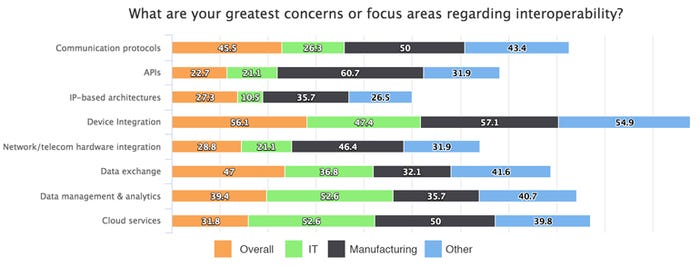

When it came to interoperability, IT and manufacturing professionals were about equally concerned about cloud services and data exchange. Device integration was a slightly higher concern for manufacturing pros than for IT. IT industry workers, meanwhile, were more concerned than manufacturing with data management and analytics, while manufacturing employees were more concerned than IT about network/telecom hardware integration, IP-based architectures, APIs and communication protocols. Among all respondents, device integration was the biggest concern.

Our survey results also highlighted that the OT landscape can be overwhelming for IT workers. The scale of OT technology is a primary reason why, said Khatri. In the past, it made sense for many organizations to think of IT staffing in terms of the ratio of IT staff to the overall number of employees, or track the average of IT spending per employee. At organizations with burgeoning numbers of IoT devices, however, it might make more sense to think of IT spending per connected device. “A typical large bank or retailer with 1 million connected devices might have 2,000 or 3,000 IT professionals, so the ratio is roughly 200 or 300 devices per IT worker,” Khatri said. “When you look at the OT space, you tend to have considerably more connected devices. Having 5 or 6 million is not uncommon.”

The sheer volume of devices used in operational technology settings is a challenge but so is the variability of such devices. “In the IT world, we are used to Mac or Windows, iOS and Android,” Khatri explained. In the OT world, there are tens of thousands of different devices and programmable logic controllers with an array of protocols such as Modbus or PROFIBUS. “Now, the OT guy is asking IT to integrate those types of devices into a broader IT infrastructure,” Khatri said.

The vastly different landscapes in IT and OT also poses challenges when it comes to security. It is often not feasible to take traditional IT security practices and simply deploy those in an operational technology setting. In OT, there are proprietary devices, and it is not uncommon for many industrial organizations to have industrial control systems that are a decade old or more. More than a third of survey respondents, 35.4% agreed that “lack of consistent security strategy across OT and IT” was a hurdle. More than one in five, 22.1%, agreed that an insufficiently secure network/wireless system was a problem.

A bigger problem, however, could be the lack of cross-functional education and training. A total of 39.8% of respondents selected this as a problem.

Addressing this hurdle takes support from senior leaders. “An organization needs top-down support for digitizing its operations,” Khatri said. Many organizations have focused on digitizing people-centric processes such as HR, customer support and so forth. “The next evolution could be creating a digital operation environment,” he added. Companies that succeed in this transition will have the freedom to explore new business models, creating digital twins and ultimately digitizing their entire product lifecycle.

Achieving these goals, however, requires new kind of workers that can synthesize the traditional IT and OT domains. “I don’t think you can find them,” said Richard Soley, Ph.D., executive director of the Industrial Internet Consortium. “I think you have to build them.”

About the Author(s)

You May Also Like