Startup Everactive Aims to Make Industrial IoT Battery-less

The startup Everactive is building battery-less technology for a growing number of industrial IoT applications.

September 6, 2019

Bob Nunn has been focused on the startup world since 1989 when he joined Vitesse Semiconductor, which then had about 30 employees. After working there for about a decade, it achieved a multi-billion-dollar valuation.

The experience was formative. “It just kind of cemented for me this idea of building teams and building companies around technology breakthroughs,” he said.

In the interim, Nunn has worked with startups that were “as small as two guys in a garage” and others with around 500 employees. A gig working as president and chief executive officer at Fulcrum Microsystems led him to Intel, where he worked in three business units. After working for the chipmaker for several years, he decided he enjoyed the startup world too much and set about imagining the best-possible startup to work for. The process ultimately led him to the battery-less sensor company Everactive, which initially focuses on providing battery-less sensing technology for industrial IoT applications.

[Industrial IoT World is the event where companies learn how to scale IIoT for integration, innovation and profit. Save $200 on your conference pass with VIP code “IOTWORLDTODAY.”]

The genesis of Everactive was when two professors who went to school together at MIT, Ben Calhoun and David Wentzloff both with specialties in ultra-low-power electronics became interested in the Internet of Things. After seeing various projections of tens of billions or even one-trillion IoT devices, they imagined what such a proliferation of devices — many of them potentially battery-powered would look like. Imagining a world with 1 trillion battery-powered IoT devices, they calculated that if batteries improved to the point that the average life span was a decade, there would be nearly 274 million IoT-related battery replacements every day.

Bob Nunn

Even in a world where there are billions of battery-powered IoT devices, the potential ramifications of periodically changing batteries contrasts with the technologies’ promise to spur operational efficiency.

“Our sole focus is to remove the battery from the IoT device so that you can generate massive amounts of new data streams and really create that idealistic world where you have as much physical data to sort through as you do with Google in the online world,” Nunn said.

But to get there and to do so without batteries is not just a matter of energy harvesting. It is more of a full-stack electronics challenge involving networking, radios and processing.

The wide-ranging technical focus made it vital for the firm to have a clear business model. Nunn decided to make that focus on data. “That’s how we came about with our business model, focused on providing full solutions to the industrial space on particular assets and environments,” Nunn said. “Then we can commercialize that by selling those insights on those assets and environments, back to the customer on a service model basis.”

The industrial market was a natural fit because of its use of powered IoT sensors and degree of sophistication and experience using data analytics tools. The degree industrial companies have deployed IoT technology has been limited by the feasibility of implementing battery- or wire-powered IoT devices, Nunn said. There are a “massive number of assets” that are “currently unmonitored,” he added.

One such application is monitoring steam traps, a common technology used in environments ranging from manufacturing to campuses and hospital environments.

“Steam is still used a lot today,” Nunn said. In his estimation, there are some 50 to 60 million steam traps installed in the world.

Many organizations use a boiler to create steam and then distribute it through pipes. Problems can arise when condensation builds up in a line, which can come at a cost of efficiency or potentially cause a safety hazard. “There are cases we’ve seen in metropolitan areas where a steam trap will get blocked, and you’ll get an explosion from a backup of water in the line,” Nunn said.

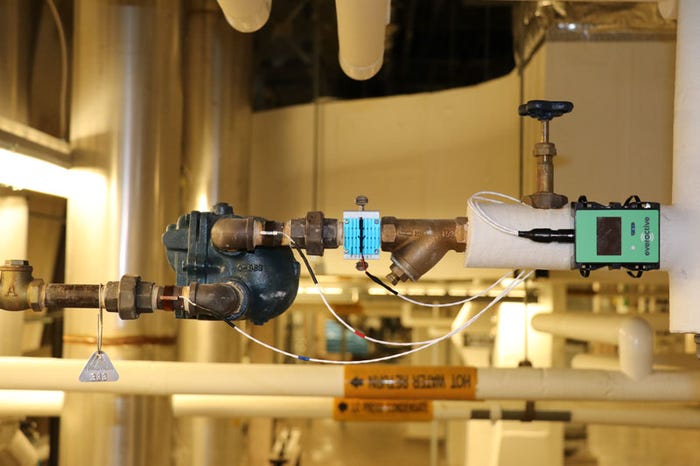

Everactive’s steam-trap monitoring technology is powered exclusively by the heat of steam pipes or low levels of indoor light.

Everactive’s focus on steam trap monitoring has opened up conversations with Fortune 100 companies, owing to the ubiquity of the technology and the potential to save energy by keeping a closer eye on steam traps. “It’s an easy conversation to have with anyone with continuous manufacturing type applications,” Nunn said. Examples include pharmaceuticals, food and beverage, pulp and paper and consumer product manufacturing. The technology is also used in district heating. “They all have the steam distribution problem,” Nunn said. While sensing technology is available to monitor this problem, the batteries of such systems must be replaced regularly — sometimes at a substantial cost.

The company’s foothold in steam trap monitoring gives it the potential to provide further insights on its steam systems over time. Examples include monitoring a boiler directly as well as heat exchangers and heating coils. “The real value is moving from individual assets to a full system,” Nunn said.

Everactive has also developed battery-less monitoring devices to keep tabs on the conditions that cause refinery flares. “They’ll give you an indication of where these pressure build-ups are coming from,” Nunn said.

Another one of the company’s systems monitors motors and rotating equipment. “There’s a lot of motors that are already being monitored, and people are really looking to extend that to more and more motors,” Nunn said. “Our mission is to extend it to all the motors, all the pumps and fans and everything that’s throughout a factory that traditionally you wouldn’t even think about.”

When asked why he chose to come to Everactive over other young companies, Nunn said he has three main criteria required for a startup to be a contender: They had to be ambitious, have funding and have unique technology.

In terms of the first, Nunn said, to get his interest, a startup must want to change the world. “It sounds silly, but we really do start with the premise that if we can pull this off, the world would be different. Everactive definitely fits that mold,” he said.

From a funding standpoint, Everactive has attracted a total of $60 million to date. Early on, NEA, the well-known venture capital firm, became a lead investor. “I’ve actually worked with them before, so that was a big checkmark for me, as well,” Nunn said.

Regarding Nunn’s technology criteria, he seeks to determine a startup’s strategy to get to market. “So having done this for a while, I can get a pretty good sense whether somebody is taking advantage of a market opening, are they working on execution or is it really a fundamental technology advantage?”

And even though Everactive ticked all of Nunn’s boxes, it was the founders who convinced him to take the leap and join the company. “Ben and Dave, besides being brilliant individuals, are just great people, and they had put together a great group of individuals,” Nunn said. When he joined, the company had roughly 30 employees. Now, the tally is more than 50.

“We really do aspire to be the next big thing. And we’re building a company with that in mind,” Nunn said. That, to me, is the fun. We are not asking: ‘Okay, how do we get acquired?’ We are asking: ‘How do we become one of the next great companies in the world?’”

About the Author

You May Also Like