IIC's Industrial Internet Connectivity Framework and Why You Should Care

The Industrial Internet Consortium's Industrial Internet Connectivity Framework went largely unnoticed, yet it holds a wealth of critical information for any company considering industrial internet implementations.

May 16, 2017

On February 28, the Industrial Internet Consortium published The Industrial Internet Connectivity Framework – a 129-page document which lays the foundation for Industrial IoT connectivity.

Unfortunately, apart from a few press releases and short posts, the document has gone largely unnoticed. After reviewing it, we realized that it contains a wealth of critical information for Industrial IoT implementation. I also had the chance to spend about an hour on the phone with Rajive Joshi, co-chair of the IIC Connectivity Task Group and one of the authors of the Connectivity Framework, asking questions and clarifying multiple points in the document.

Our conclusion is that the Connectivity Framework is a valuable way to assess Industrial IoT technologies and protocols and represents a great leap forward towards a common framework. This offers significant benefits for multiple parties, including:

for those responsible for implementing industrial automation solutions – especially in manufacturing, utilities, healthcare, smart cities and other industry verticals where capturing and sharing data is still a major challenge

for technology companies serving the above industry verticals interested in both securing lasting value and expanding their offering

for standards defining organizations (SDOs), working on industrial IoT standards.

The companies that actively contributed to the document were RTI, Cisco, Ericsson, Nokia – plus Itron, Kepware, Fujitsu, Samsung, AT&T, SAP, ABB, GE – just to name a few. Notably, we did not see many semiconductor players participate in this effort.

It’s hard to do justice to the document in this post. We decided it would be critical to try to digest the 129 pages down to the most essential elements and provide our summary as to why we believe this document is so critical and what needs to be done next.

Currently, the Industrial IoT space – from manufacturing to utilities to healthcare and so on – reminds us of the Tower of Babel and the confusion of languages: currently there are multiple systems, very often proprietary and siloed, speaking different protocols unable to communicate with each other.

In manufacturing alone we have OPC-UA, Modbus, Profinet, DDS, Web Services with RESTful APIs and many others, some much more open than others. There are multiple connectivity standards and options, which creates a nightmare for business & technology executives alike in charge of implementing IoT solutions. This is one of the key technology impediments slowing down roll out of IoT systems.

We can’t expect industries to converge on a single connectivity format or a single protocol – it would be unrealistic and impractical. However, having a common framework which multiple industrial players can agree on can make these multiple connectivity technologies and protocols interoperable and easier to manage.

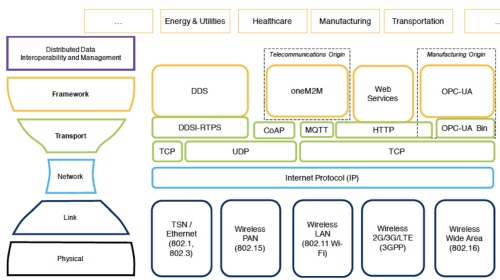

For connectivity specifically, we still often use either the OSI 7 layer model, originally published in 1984, or the Internet 4 layer framework. Both of these models were primarily designed for networks of people, not necessarily things, and both are outdated when it comes to Industrial IoT – as the whole approach to data and applications in IoT has grown much more complex in the past decade.

Not only do we care more about data, but also about data in specific user contexts. Data needs to be discovered, published, subscribed to, requested and replied to; exceptions need to be handled in a consistent manner – as more data functions get added over time, and the model needs to be flexible enough to accommodate the new functionality. The IIC’s attempt to define a much better suited framework that addresses data in motion is admirable.

The approach proposed in the Connectivity Framework allows treating multiple verticals and their technology stack in a similar and consistent fashion. It empowers the industrial users of IoT connectivity to clearly compare various connectivity technologies along a consistent set of criteria as to how well they address quality of service, and ask more specific questions about their architecture and to what extent it is future proof.

The criteria cover both functional and non-functional requirements of connectivity, such as: performance, scalability, reliability, resilience, security and safety – to name a few – in much detail. It creates an assessment template for connectivity solutions and platforms, providing a tool to compare “apples to apples” and discover early if problems may arise when implementing a particular solution.

When it comes to data interoperability, the Connectivity Framework does not stop short there – another very important point of the Framework addresses common data format and structure (a.k.a. syntactic interoperability) – making sure data flow is consistent and eliminating data errors along the way.

Data structure interoperability (syntactic interoperability) is a critical pre-requisite for the interoperability of meta-data, assigning meaning to data (a.k.a. semantic interoperability), which is a critical element for the seamless communication among industrial machines and with other services. The Framework opens the possibility for the industry to further collaborate on semantic interoperability.

The Connectivity Framework also opens up a marketplace for connectivity gateways, creating more choices for developers. Connectivity gateways put themselves between domain specific connectivity technologies (sometimes a de-facto domain connectivity standard) and core connectivity standards, allowing the data to flow seamlessly and in a consistent manner between the domain specific environment and a standardized network.

While the Connectivity Framework does not define standards in and of itself, it lays the foundation for SDOs (Standard Defining Organizations, such as the ISO and more specialized industry-specific standards organizations) to work on defining industrial IoT standards for multiple verticals to utilize a common framework.

In summary, the Connectivity Framework at a very minimum forms the basis for those responsible for selecting IoT platforms to compare multiple solutions in a consistent way and determine the gaps; it allows IoT technology developers and system architects to map their technology stack against similar solutions in the industry in a more “apples-to-apples” fashion; it offers the industry an opportunity to converge on vertical applications and data interoperability; and finally, it lays a foundation for SDOs, making standardization efforts much easier.

As for the future of the Connectivity Framework, the collaboration and support of the major IIC stakeholders should give it great momentum to get implemented. Many aspects of it will take years to develop and populate; however, the document itself will propel the industry forward by a few years – saving a lot of time in building consensus.

— Daniel Obodovski, Founder & CEO, The Silent Intelligence

About the Author(s)

You May Also Like

.png?width=700&auto=webp&quality=80&disable=upscale)

.png?width=700&auto=webp&quality=80&disable=upscale)

.png?width=300&auto=webp&quality=80&disable=upscale)

.png?width=300&auto=webp&quality=80&disable=upscale)

.png?width=300&auto=webp&quality=80&disable=upscale)