The concept of IoT vending machines has is becoming mainstream. Here, we talk to vending machine telemetry firm Vendon and its partner, AT&T.

July 24, 2019

In 1966, the German computer scientist Karl Steinbuch predicted that “in a few decades’ time, computers will be interwoven into almost every industrial product.” While that prediction was perhaps slightly ambitious, primitive Internet of Things devices did begin popping up in the 1980s and 1990s — before the term “IoT” existed. In the 1980s, for instance, Carnegie Mellon researchers rigged up a Coke machine with sensors to keep tabs on the machine’s contents and connected the device to ARPANET, the predecessor of the modern internet. After the upgrade, the researchers could know without walking to the machine whether it was stocked.

Fast forward to today and several companies have commercialized more-sophisticated IoT vending machines. One of them is Vendon, a Latvian company that partnered with AT&T Internet of Things (IoT) solutions group to link its business intelligence and telemetry tools for coffee and vending machines to the cloud. Doing business in more than 75 countries, Vendon counts some of the largest food and beverage brands internationally as customers.

To learn more about the company and its partnership with AT&T, we spoke with Andrey Sergeyev, chief customer officer at Vendon and Kelley Duarte, vice president of AT&T’s IoT and strategic services group responsible for Europe, the Middle East and Africa.

Can you give me a brief overview of the history of Vendon and its involvement with IoT vending machines?

Andrey Sergeyev: Our Vendon business intelligence and telemetry solution was born out of a simple request for an SMS payment solution for vending machines, and eventually developed into a complete solution for improving operational efficiency and accelerating business growth in the global vending and coffee industry. Founded in 2011 as a two-person team based in Latvia, Vendon has grown to become one of the leading export companies in the Draugiem Group with thousands of customers in more than 75 countries. One of our founders and current chief technology officer, Edgar Bināns, was previously a developer at MapOn, another company in the Draugiem Group (one of the largest technology companies in Latvia), and spent months on creating the software for the first Vendon solution’s prototype together with an electrical engineer who constructed the hardware device. The first tests were carried out at the Draugiem Group’s office in January 2010. The same year, meetings with customers led to the realization that the device and the accompanying software they had created could be much more than just a text-message payment solution. Instead, with some tweaks, it could serve as a business intelligence and telemetry solution for vending businesses, and thus Vendon was founded in 2011. Later, as the business grew, Vendon expanded their solution into a fast-growing coffee business segment.

Andrey Sergeyev: Our Vendon business intelligence and telemetry solution was born out of a simple request for an SMS payment solution for vending machines, and eventually developed into a complete solution for improving operational efficiency and accelerating business growth in the global vending and coffee industry. Founded in 2011 as a two-person team based in Latvia, Vendon has grown to become one of the leading export companies in the Draugiem Group with thousands of customers in more than 75 countries. One of our founders and current chief technology officer, Edgar Bināns, was previously a developer at MapOn, another company in the Draugiem Group (one of the largest technology companies in Latvia), and spent months on creating the software for the first Vendon solution’s prototype together with an electrical engineer who constructed the hardware device. The first tests were carried out at the Draugiem Group’s office in January 2010. The same year, meetings with customers led to the realization that the device and the accompanying software they had created could be much more than just a text-message payment solution. Instead, with some tweaks, it could serve as a business intelligence and telemetry solution for vending businesses, and thus Vendon was founded in 2011. Later, as the business grew, Vendon expanded their solution into a fast-growing coffee business segment.

What led to the partnership between AT&T and Vendon?

Kelley Duarte: For a global and fast-growing company like Vendon, reliable and global connectivity is vital for the business. Vendon works with some of the largest food and beverage brands in 75 countries around the world. It’s responsible for delivering expert solutions that allow its customers’ businesses to become more efficient and manage their costs. Given its global customer base, Vendon needed reliable and fast connectivity that has a global reach to support its customers. This is why it turned to AT&T.

Kelley Duarte: For a global and fast-growing company like Vendon, reliable and global connectivity is vital for the business. Vendon works with some of the largest food and beverage brands in 75 countries around the world. It’s responsible for delivering expert solutions that allow its customers’ businesses to become more efficient and manage their costs. Given its global customer base, Vendon needed reliable and fast connectivity that has a global reach to support its customers. This is why it turned to AT&T.

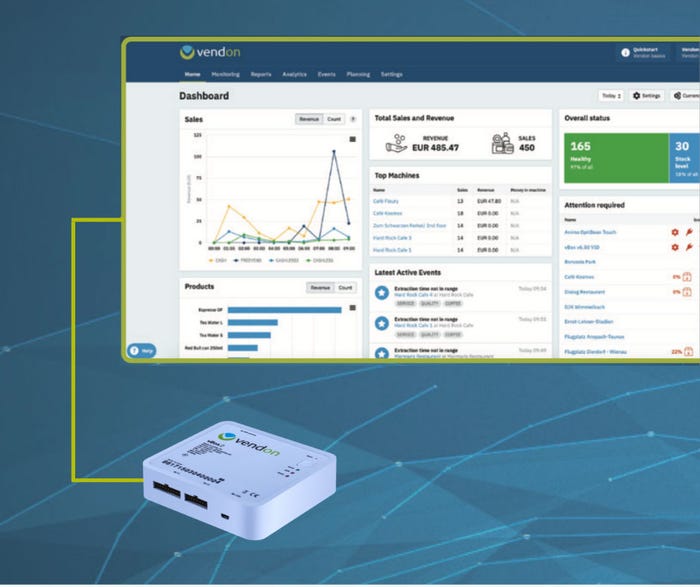

Our AT&T IoT solutions are used to boost the performance of the Vendon vBox, Vendon’s IoT hardware device that its customers can install directly into their vending machines to activate the telemetry solution. This offers Vendon customers near-real-time technical and sales data to guarantee snacks and drinks are always available and match the consumers’ preferences. Powerful reporting and analytics tools in the Vendon Cloud also provide valuable insights into consumer behavior and product performance. This information allows a business to make informed decisions that, in turn, help to retain or win more customers and grow revenue.

The AT&T IoT solution used in the Vendon vBox comprises of the AT&T Global SIM and AT&T Control Center. It will transport data about the coffee and vending machines from the Vendon IoT hardware device and to Vendon’s cloud computing application service. The AT&T Global SIM provides highly secure connectivity in more than 200 countries and territories. This means Vendon can provide quality customer service and ensure coffee and vending machines are maintained and managed remotely and automatically. It doesn’t matter if they are installed in a London office kitchen or at a gas motorway station in California.

Andrey, can you tell me more about the business intelligence you help offer?

Andrey Sergeyev: Business needs in the coffee and vending segments are similar, but there are also some differences, based on the specifics of each business, their end customer and business models. Traditional vending businesses serve cold drinks, hot drinks (mostly coffee), snacks and fresh food in so-called free-standing vending machines. Coffee businesses operate so-called tabletop coffee machines. These are professional coffee machines that you see in petrol stations, coffee shops, supermarkets, offices. Four main factors help all these businesses to succeed: the machine should always be in working condition, requested products and drinks should be always available, the machine should have the right mix of products and drinks at the right time matching consumers’ preferences, and consumers should be able to get the requested product or drink. The main pain points Vendon helps to resolve are:

Avoiding machine downtime by providing notifications in near real-time.

Avoiding unnecessary visits by helping to plan efficient routes for refilling based on current and future consumption trends.

Making sure the machine’s products always appeal to consumers, by helping to stock the right products and in the right quantity based on sales data and consumption trends.

Tracking beverage recipes and components consumption.

Customers have peace of mind, knowing remotely and in near real-time what is happening with their fleet, and allowing them to manage their machines and maximize revenue remotely.

There are also differences between the coffee and vending business segments, including the number of products, maintenance aspects, need for different payment methods, and business models.

Customers are overwhelmed with various data coming from machines, locations, consumers and their team. They need insights that help them make business decisions faster. Our business intelligence tool transforms a tremendous amount of data into actionable and valuable insights about consumer behavior, product and machine performance. All this happens in real-time. If a consumer bought a cup of coffee, you will be able to see it almost right away in Vendon Cloud. Customers can also generate different in-depth reports that help them to dive deeper into specific aspects. Here are a few examples of how business intelligence tools helped our customers to grow their businesses:

Challenge: The largest stream of customers was observed during 7–8 a.m., while Vendon Cloud showed that coffee sales were at their highest between 8 and 9 a.m. Upon further analysis, it was discovered that pastries are delivered to the shop at 8 a.m., which is one of the factors that drive coffee sales.

Result: By adjusting the delivery time of pastries to 7 a.m., coffee sales grew to match the stream of customers.Challenge: If the coffee operator rents the machine free of charge and their main stream of revenue comes from coffee bean sales, it may become challenging to earn enough on bean sales for the business model to be sustainable.

Result: With Vendon, our customers compare the actual cups made with coffee bean sales to determine whether the beans are sourced directly from the operator or elsewhere. That way, gaps in revenue are filled, which would not be possible without IoT.Challenge: One of the main factors in a long machine lifetime is proper maintenance. If it falls on the end customer (where a machine is installed) to take care of it, the operator may not have all the tools to follow up to ensure the machine in being properly maintained.

Result: With Vendon, customers see whether the machine is cleaned at regular intervals, and whether it’s used directly after the final cleaning of the day. This extends machine lifetime, prevents unnecessary maintenance visits, and ensures that coffee quality does not change. For coffee operators, this data can be used to justify the right to refuse warranty services if proper maintenance has not been carried out.Challenge: Price changes are always a sensitive topic with customers, but the impact of a lower or higher price is not always clearly apparent, hence finding the optimal pricing model can be difficult.

Result: With Vendon, it becomes easy to check the price sensitivity at a given location. All sales data is readily available, and prices can be changed remotely, which means that operators get an immediate response to whether price changes have any impact on sales performance. Through such experiments, one of our clients discovered that a 20% increase in price does not affect sales volumes at all.Challenge: Without IoT, filling the machine with top-selling products takes a lot of guesswork and places a huge responsibility on the refiller to inform the product team that some items are constantly sold out while some stay unsold for extended periods of time.

Result: Vendon Cloud has a product shelf analysis section that provides recommendations based on historical sales data – that way, the machine is emptied out more evenly, as the top-selling products are stocked in larger quantities, which leads to an increase in turnover and fewer refill visits. For one of our clients, machines reached twice the industry average when they began analyzing product sales.

What is the competitive market like for vending- and coffee industry–related telemetry? What sets Vendon apart from the competition?

Andrey Sergeyev: The vending industry historically operated in a very traditional way, doing many things manually and on paper. Only few companies embraced new technologies and started their digital transformation journey. When Vendon started, we were an industry pioneer in Europe and globally, educating the market long before IoT in the vending and coffee industry became a trend. Within the last 4-5 years we’ve experienced a huge number of customers embracing the new reality with a focused effort on making their machines “smart”, thus gaining a competitive advantage and providing a superior customer experience.

Along with this, we also saw a growing number of similar solutions for the vending industry – from machine manufacturers to technology providers. These solutions are mostly suited for vending businesses or for a specific machine manufacturer. Again, as industry pioneers, we saw a fast-growing coffee business segment as an opportunity and improved Vendon’s solution to serve the needs of coffee businesses too. Vendon provides a unique business intelligence and telemetry solution for coffee businesses, helping to manage the whole fleet of different kinds of machines, as we are intentionally focusing on this segment. We’ve also developed unique technical competence that allows our solution to work with the largest number of different machines (both for vending and coffee businesses) – our solution is compatible with more than 700 machine models from more than 45 manufacturers worldwide. To our knowledge, no competition is able to match this at the quality the market expects.

How can you help retail coffee establishments maintain the quality of their beverages?

Andrey Sergeyev: In order to maintain the quality of beverages, there are several important factors that need to be taken care of. Drinks should be served based on a certain recipe. Milk temperature should be maintained at specific levels. Machines need to be cleaned on a regular basis to avoid issues such as leftover milk drying up in the milk lines or mineral scale build-up. Recently, water quality is becoming an important aspect for many coffee businesses too. With the Vendon solution customers can set up and track beverage recipes, to see not only what was served (latte, cappuccino, etc.), but also what individual ingredients of a specific drink were consumed and in what quantity. It is also possible to see when a specific machine was cleaned in real-time. With some add-ons, customers can track milk temperature and water quality. This helps to maintain recipe and beverage quality and spot problems remotely.

Does AT&T also work with other companies to help extend connectivity to café equipment?

Kelley Duarte – We are a major player in the connected vending machine space, including food service and beverage machines. Notification of inventory levels, geotracking and payment processing are the typical use cases for connected vending machines that we support. Maintenance support is another use case for both the coffee machine and other vending products we support. The owner can get service codes and alerts to assist with keeping the machines running properly.

More broadly, at AT&T we’re world leaders in global business communications, and because of IoT, we’re changing the way businesses interact with their customers, other businesses, and the world around them.

Whether it’s the driver of a connected car, or a plant manager who operates a connected factory, we’re connecting people and businesses to things to create more efficient and streamlined processes. We’re structured to deliver adaptable solutions across many industry verticals, including asset management, vehicle solutions, consumer electronics, drones, energy, healthcare, manufacturing and smart cities – or in this use case, vending and coffee machines.

We’re helping businesses gain competitive advantage by harnessing data to predict, learn and make near-real-time decisions through IoT. From IoT platforms to professional services, we’re working across many vertical industries to help businesses optimize processes, enhance security, gain insights, and solve complex problems. Our network and innovative platforms give our customers the tools to do just that—where they want it and how they want it—around the globe.

The future will demand near-instantaneous connectivity for everything — from drones to virtual reality devices. As an integrated communications company, we can provide the end-to-end connectivity to power these exciting new-world demands in industries as specialized as the coffee space.

About the Author(s)

You May Also Like

.png?width=300&auto=webp&quality=80&disable=upscale)

.png?width=300&auto=webp&quality=80&disable=upscale)